Resin Molds Simplified: A Fun Guide to Custom Creations

Making molds from resin is an enjoyable and rewarding process that lets you bring your ideas to life. Whether you’re a seasoned crafter or a beginner, this guide will walk you through the simple steps of making your mold for epoxy resin. With just a few materials and a bit of patience, you can create distinctive resin projects that showcase your individuality.

Materials You’ll Need

Before beginning the process, collect the following items:

- Silicone Mold Kit : This is the primary material to create your mold. Find a mold kit that has easy-to-follow instructions on packaging.

- Measuring cups: You’ll require these cups to determine the hardener and resin proportions accurately.

- Mixing Sticks: They can be used to stir the resin mix.

- Mold Box Mold Box container that can hold your silicone as it sets.

- Glue Gun: It is useful for securing the mold box and any other accessories you’d like to put in your mold.

- Release Agent (optional) This allows for an easy demolition later.

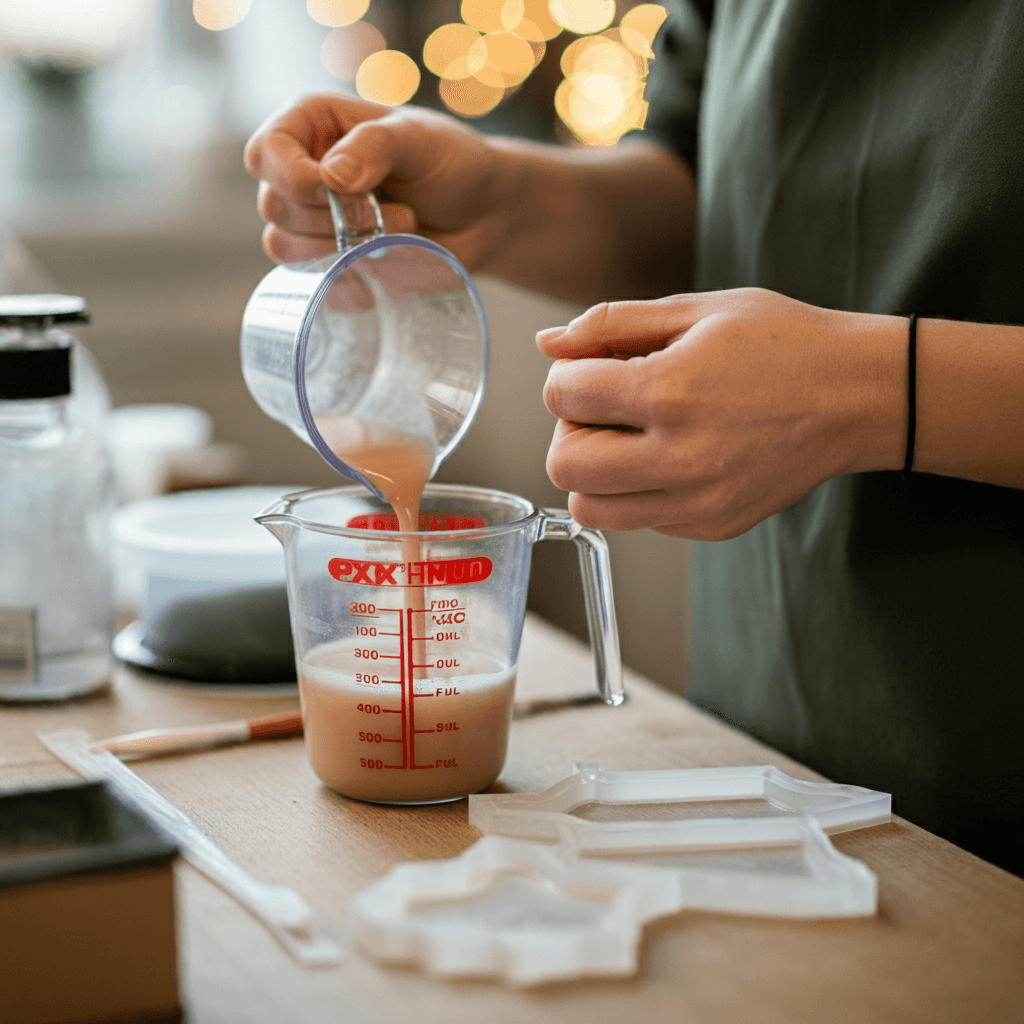

Step 1: Measure the Ingredients

Begin by reading the package instructions for your mold kit made of silicone. The majority of kits require mixing equal amounts of hardener and resin. Make use of measuring cups to ensure accuracy since slight variations can alter your final result.

Step 2: Mix the Resin

After you’ve determined the equivalent proportions of hardener and resin:

- Pour them into the mixing cup.

- Make use of mix sticks.

- Mix both components well.

Mix thoroughly so that there are no bubbles or unbalanced curing is essential. A consistent mix will give more results, so be patient with this process.

Step 3: Prepare Your Mold Box

When your resin mixture is ready, you can prepare the mold container. If you’re making a DIY mold box, be sure that it’s secure and clean. If you need to, use a glue gun to secure the sides. The mold box must be strong enough to support the silicone without leaks.

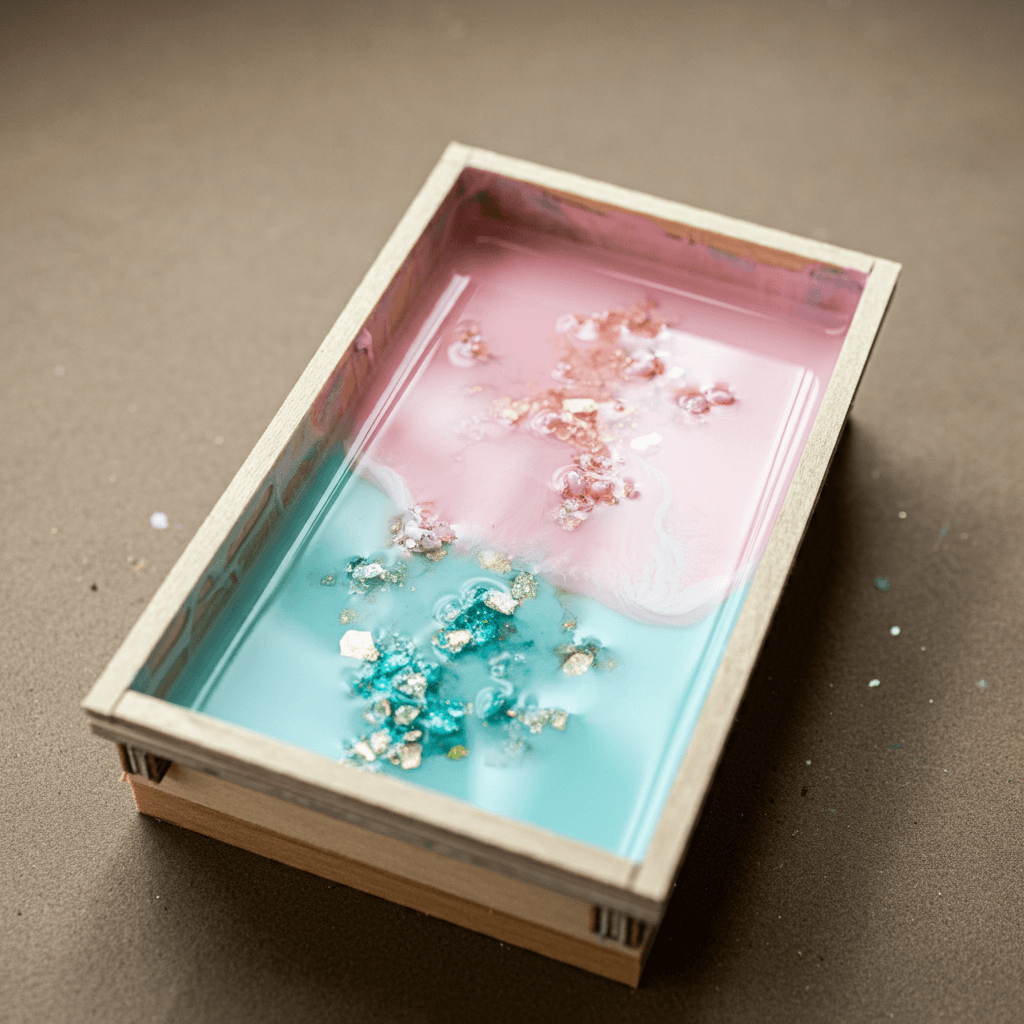

Step 4: Pour the Mixture

After your resin has been mixed, slowly place it inside the mold. If you’re embedding items, like ornaments or charms, put them into the mold box prior to pouring the resin onto them. Be sure to pour slowly to prevent bubbles from forming and ensure even coverage.

Step 5: Allow to Cure

Let the mold set according to the directions provided in the silicone kit. This is a crucial step because it determines the strength and endurance of the mold. The mold’s curing process can last from between a couple of hours and all day. Do not touch or move it during the curing period to ensure that it’s set correctly.

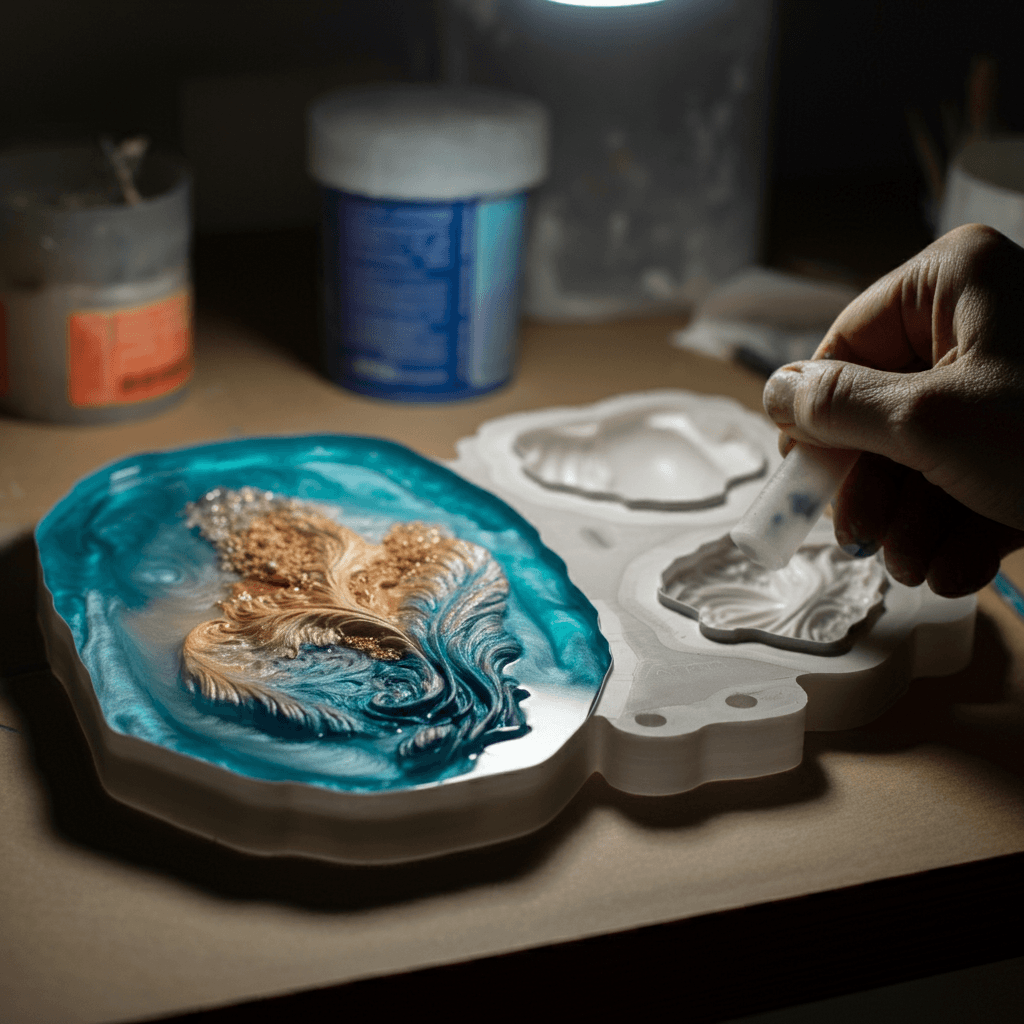

Step 6: Demolding Your Creation

When your mold has fully cured, it’s now time for the most exciting part, de-molding! Remove the mold carefully from the container. The removal process will be straightforward if you’ve used an agent for release. If not, you can gently remove the mold on the edge. Remove it carefully so you don’t damage or tear the mold.

Tips for Successful Resin Projects

- Take your time, doing it too fast could result in less-than-ideal outcomes. Always adhere to the recommended timeframes.

- Play around with designs. You can create diverse forms and patterns once you’ve made the first mold. Make use of multiple mold boxes for different tasks.

- Safety: always wear gloves and work in a ventilated area when working with resin. Certain resins emit gases that could affect your lungs.

Common Mistakes to Avoid

- Untrue Measurements: Ensure that you are measuring equal parts accurately. Improper ratios can lead to an uncured or sticky resin.

- Mixing is vital; mixing too much can cause bubbles to form. Mix gently, but beware of mixing too vigorously.

- Avoiding Cure Time Don’t rush and wait for the resin to fully cure prior to demolding. Removal too soon can cause distortions.

Conclusion

Making your mold to make resin is satisfying, as it tests your creative side and creates unique resin creations. With these steps, you can create top-quality molds for your crafting requirements. Be sure to take your measurements meticulously, thoroughly mix, and deform the mold with diligence. If you can master it, you can create beautiful resin pieces that show your style. Gather your supplies. Follow this step-by-step guideline, and begin your resin-making journey now!

1 thought on “Resin Molds Simplified: A Fun Guide to Custom Creations”